Domin Valves

Performance and Efficiency, Perfected.

Domin Valves

A Detailed Look

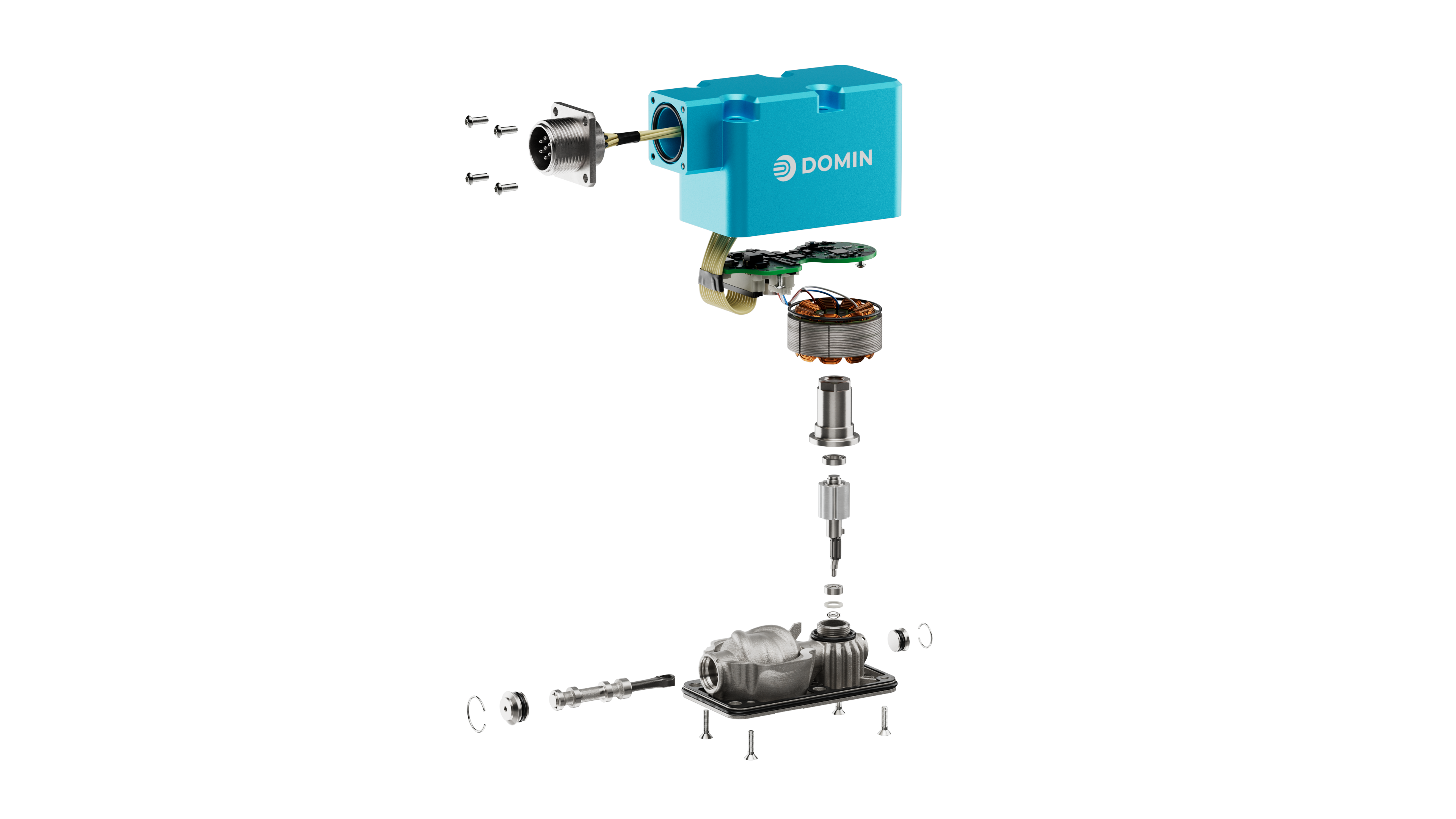

Pioneering Additive Manufacturing

This patented process for servo valve manufacture allows for ultra-compact design and unprecedented capabilities.

Dominating Miniaturisation

Our slim on-board electronics enable valuable weight and space savings. Proprietary control algorithms optimise performance by minimising overshoot and maximising responsiveness.

Revolutionising Precision

Traditional linear transducers are bulky and cumbersome. Domin utilises ultra lightweight magnetic hall-effect sensors that offer unparalleled resolution and control accuracy.

Unmatched Power Delivery

Highly compact three-phase brushless DC motors deliver exceptional force output for a given electrical input, ensuring precise control even under high pressures and frequencies.

Trusted By

Domin Valves

Discover the Benefits

Traditionally, engineers have faced a trade-off between two-stage valves, which provided high speed and precision but were notoriously inefficient, and direct drive valves, which prioritised energy efficiency and robustness but often sacrificed speed and size. Recognising this challenge, Domin set out to develop a groundbreaking solution that delivers the highest levels of both efficiency and performance, without compromise.

Our valve technology exemplifies the pinnacle of performance, offering unmatched power density. The flexibility of metal 3D printing enables the creation of highly precise components that eliminate unnecessary bulk, minimising waste and maximising space efficiency.

Domin

What Our Clients Are Saying

Saving money with better performance.

We’ve been waiting a long time for an extremely rugged servo valve that holds up in the forest industry. We didn’t expect this valve to be so cost-effective and handle extreme vibration at high cycle rates. With a very small footprint and as a drop-in replacement for Bosch, Moog, Parker, and Woodward. We now stock several valves for a wide range of applications. Saving money with better performance.

Peerless Engineering

Sales Manager

Much better than the Moog D633.

The valves was within specs (in terms of pressure drop and response time) and was much better than the Moog D633. This is very good news for the future tests we will be performing.

PYTHEAS Technology

Head of R&D

The valve can handle very difficult control situations.

The Domin S6 Pro is a high-performance valve that competes very well with the other major manufacturers in terms of motion control performance, particularly with position and force control. The linear response of control output to flow of the valve allows it to be tuned easily and the response time and bandwidth are very good. The valve exhibits excellent force control and is very stable during motion. In the testing we performed, we were not able to get the valve to misbehave or go unstable, which means the valve can handle very difficult control situations.

Delta Motion

President

The Domin valves have proven to be very rugged and reliable with outstanding performance.

We have now fully transitioned from the Woodward HRT 15 gpm servo valve to the Domin S6 Pro servo valve for piloting the Olmsted 32mm, 40mm, 50mm, and 63mm high performance cartridge valves.

Visi-Trak Worldwide LLC

President

Domin Valves

Answering Your Questions

YOU MAY NEED TO KNOW

Frequently Asked Questions

Why do You Use Additive Manufacturing?

Additive manufacturing enables precise design and production, allowing us to optimise flow channels using advanced simulation techniques. This achieves minimal pressure drops and enhanced flow efficiency. By printing only the necessary material, we reduce waste significantly. The result is ultra-compact valves that are optimised for flow, weight, and size, delivering superior performance.

Are Domin Valves Servo or Proportional?

Domin valves combine the advantages of both servo and proportional technologies. Servo valves are known for their compact size and dynamic response, suitable for simulation and testing. Proportional valves are robust and reliable, ideal for industrial uses like processing and moulding. Our innovative design marries the high performance of servo valves with the durability of proportional valves for versatile applications.

How Easy is it to Upgrade to Domin Valves?

Upgrading to Domin valves is straightforward and hassle-free. Our valves are designed to be interchangeable with the commonly used ones in existing applications, fitting popular port patterns such as S01, S04, NG06, and NG10. This compatibility ensures an easy plug-and-play upgrade process.

Are Domin Valves Suitable in Harsh Environments?

Domin valves excel in harsh environments, designed to withstand high shocks, vibrations, and temperatures. Our design process eliminates common failure points seen in competitive products, such as small control orifices and seals vulnerable to high-pressure. Our powerful drives increase contamination resistance, ensuring our valves perform reliably and accurately over their lifespan.

Contact Us

Insights

Case Study

Pushing The Boundaries with INEOS Britannia

The waterborne equivalent to F1 has international teams competing for supremacy across a wide range ...

Keep Reading

Blog Article

Enhancing Hydraulic Systems

Precision control, accurate motion, and short cycle times are crucial in the test and simulation ind...

Keep Reading

Whitepaper

Transforming Motion Control

Hydraulics are integral to many industries, powering machinery in manufacturing, aviation, automotiv...

Keep Reading.png)